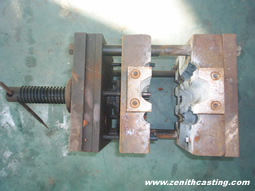

Aluminum and brass gravity casting mold

Aluminum gravity casting molds can be separated into two kinds: one is for machine assisting aluminum gravity casting process;the other is for hand work aluminum gravity casting process.These two kind of gavity casing mold can work out identical products.On such point of view, their functions are the same.However, the mold for aluminum gravity casting machines, are used for automatic mass prodcution, thus it is much expensive.The other type of mold is only for hand work gravity casting,thus can be much cheap.

These two kinds of mold always have a same mold core just depended on the detailed features of the desired product.The mold for aluminum gravity casting must have some extra systems, at least the mold frame for being fixed on the machine. Even an advanced gravity casting machine may require other systems like ejection system, water cooling system, and specilized sprue system. Compared with such complicated mold, a gravity casting mold for hand work can be much simple and much cheap. It only needs a mold core with sprue system,and a versatile mold base.

Because the brass gravity cast parts are always smaller parts. And a samll mold performing by gravity casting machine will lead to more production time therefore more production cost. So we always use the nude mold to perform casting rather than use a gravity casting mold.

The difference between gravity casting mold and high pressure die casting mold

The advantage of casting by gravity casting mold over that of sand casting mold

FAQ's about gravity casting mold,permanent mold

what is a gravity casting mold?Is the gravity casting mold the same as a permanent mold?

Can gravity casting mold be used with sand core? what's the difference between a gravity casting mold and a high pressure die casting mold?

Quick Inquiry of Casting

For any question about aluminum or brass sand casting and gravity casting, please contact us directly via following means:

P:Ms.Elandy Chen

T:+86 574 8865 1898

E: sales@zenithcasting.com